Transparent wood will replace glass in our windows?

Swedish scientists have developed technology to produce transparent wood that could replace glass in our windows in the future. The material has excellent mechanical and thermal properties and could serve as an alternative to current building materials.

In an age of glass and steel structures, wood may seem old-fashioned. Not necessarily. Researchers from the Kroof the Levon Institute of Technology in Sweden based on wood, they created a material thatory is not only durable, but also transparent and capable of storing and releasing heat.

Scientists say the material can be successfully used to build energy-efficient homesow. They are also working on a biodegradable version of the material to increase its environmental benefits as an alternative to plastic, glass and even cement.

– We prepared a multifunctional material. It transmits light well and also stores heat. We combined these two functions in one material,” said CéLine Montanari of KroLeibniz Institute of Technology in Stockholm. The material was presented at the American Chemical Society meeting in Orlando.

The scientists relied on their earlier work published three years ago in the journal to create the transparent wood „Biomacromolecules”. In the manufacturing process, they used the wood of the woolly cucumber, a species of tree commonly referred to as balsa. They removed the lignin – one of the basic components of theoin the wood, whichowhich gives it strength, but also absorbs light. They introduced acrylic in place of lignin. He filled the zar with itowno small pores left by the removal of lignin, as well as empty vessels thatore responsible for transporting water in the tree. This not only helped to maintain the structure of the wood, but also przywrocated its strength after removing the lignin and improved its optical properties. The result was a matte material based on wood.

In the latest work, acrylic was mixed with another substance called polyethylene glycol (PEG), whichory perfectly penetrates deep into the wood. The researchers were also interested in another property of PEG: when heated (about 30 degrees. Celsius) melts and absorbs energy, but when the temperature drops it hardens, releasing the previously absorbed energy.

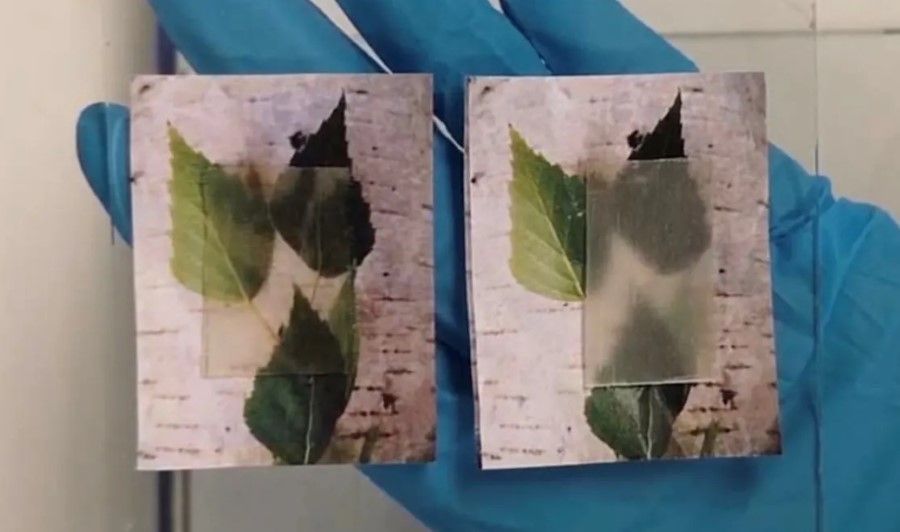

The wood-based material prepared in this way goes from p when heatedołtranslucent into transparent and can be used to make buildingsoin more energy-efficient. It captures the energy of the sun’s rays during the day and releases it after sunset into the interior.

Montanari admitted that currently large amounts of glass are used in construction, but this has a disadvantage because glass is a bad insulator, so there is a lot of heat loss. – Our wood is really amazing. It is about 10 times better insulator than glass. 100 g of this transparent material can absorb up to 8,000 J of heat – she said.

But there are rotion of polyethylene glycol, whichore melt in rotion at different temperatures. This can be used to make compositeoł mohead to adapt the properties of transparent wood to its application.

Materials containing substances thatore can store and release heat, are not a new idea in the construction industry. This is a rather novel form of insulation to reduce energy consumption. The authors of the new material, however, say their approach is different because it uses a natural material thatory reduces the need for petroleum-based materials, which involves CO2 emissions into the atmosphere.

Modified wood is not perfectly transparent when PEG is in solid state. The material has a white haze similar to frosted glass. Acquires transparency as PEG melts away. But Montanari is convinced that these challenges can be overcome by improving the chemistry used in the manufacturing process or by using rotional speciesow wood.